Features

Process Control

Pulp

Taking control of variability in the pulp mill

Advanced process control modules combine model predictive control, soft sensors and pulp tracking

November 4, 2019 By Martin Fairbank Ph.D.

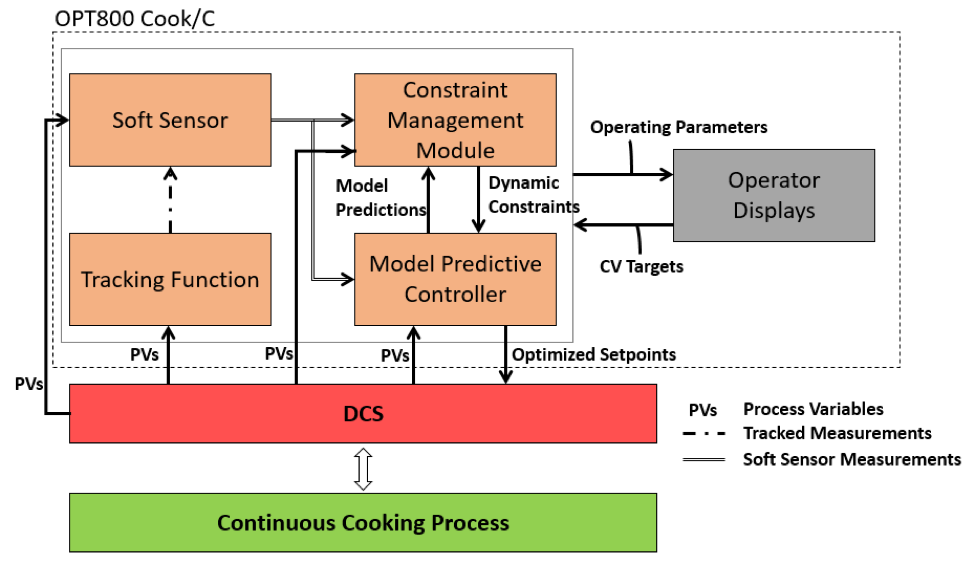

Figure 1: Continuous digester control system. Photo supplied by ABB

Figure 1: Continuous digester control system. Photo supplied by ABB In today’s pulp and paper industry, especially for commodity products in a stable or declining market, it is difficult for producers to improve profitability by increasing output, since there is no guarantee that extra product would find a buyer. One avenue that can be explored to improve the profitability of kraft pulp mills is to reduce their process variability, which can lead to cost savings from reductions in energy usage, chemical usage, off-spec tonnage and even maintenance downtime.

Process variability can have a number of causes, including raw material variation, sensor drift, control loop tuning, grade changes and human factors. The implementation of advanced process control strategies can minimize this variability and many producers are implementing these strategies in pulp and paper mills globally.

ABB has developed advanced process control (APC) modules it calls the OPT800 series, which fall under its ABB Ability optimization solutions for pulp mills. ABB has installed over 100 APC applications in the pulp and paper industry, including 20 in the last four years. I recently interviewed Dr. Abhijit Badwe, subject matter expert and business development manager for advanced process controls at ABB, to learn more about how his company helps implement APC.

Control is accomplished by applying a combination of predictive controls and pulp-tracking techniques to reduce variability. Pulp tracking is a concept that can track the performance of various key pulp properties through the process, such as moisture content in wood chips, pulp conductivity in brown stock washers, or chemical dosage in the first stage of bleaching.

These process variables are tracked in space and time up to the location of interest. These transformed variables help build a soft sensor model that is then used in the appropriate APC module for online prediction of controlled variables. If off-spec pulp is produced for ten minutes at the digester, for example, the system can predict when this slug of pulp will reach the various bleaching stages and adjusts bleaching parameters accordingly.

The pulp-tracking module also serves as a diagnostic and visualization tool for the operators. For example, if off-spec pulp or increased variability is observed at an intermediate stage in bleaching, the operator can drill down and determine the possible source(s) of this variability: off-spec process parameters in an upstream operation or even issues with wood chip quality.

Furthermore, in the case of grade changes, the tracking function aids in accurate prediction of when the new grade would arrive at a given location along the fibre line. This helps in appropriate adjustment of recipe parameters to minimize production of mixed/intermediate grade pulp.

ABB’s OPT800 modules are designed for specific stages of the pulp process that combine a number of techniques, including traditional model predictive control (MPC), soft sensors, pulp tracking, and a patented novel “constraint management” module, which calculates new low and high constraints for manipulated variables (MVs) dynamically.

The constraint management module enables the use of the tracking function in coordination with predictive controls to help pulp process controls that are typically characterized by nonlinearities, slow dynamics and highly interacting multivariable relationships amongst key process variables. This patented approach helps in taking corrective actions before the damage is done (a variability increase) as opposed to conventional controls that act after off-spec quality is detected/measured.

Applications of APC in the pulp mill

The main areas of the fibre line in a pulp mill that can benefit from variability reduction are pulping, brown stock washing and bleaching. For example, in figure 1, APC can be applied in a continuous digester. In this case, the following variables are controlled:

- Kappa number (as estimated in the cooking zone)

- Residual alkali at extraction

- Chip level in the digester

- Blow consistency

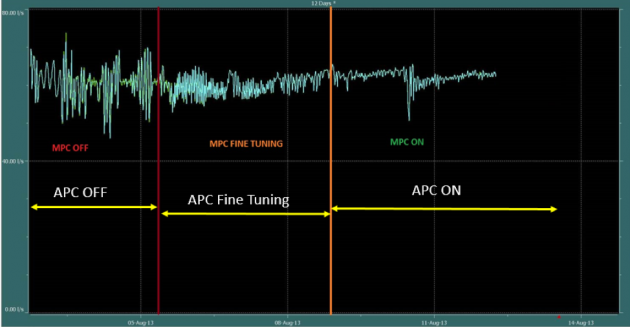

Typical results of APC implementation in the digester include reduced variability in Kappa number and reduced steam consumption, resulting in lower energy and bleaching costs (Figure 2).

Figure 2: Stabilized production rate in a continuous digester reduces variability. Photo supplied by ABB

Brown stock washing

In the operation of brown stock washing, the main objective is to achieve removal of impurities in the pulp with a minimum of fresh water consumption. Poor performance at the brown stock washers can significantly affect the stability of operation and result in increased operating costs due to higher energy requirements at the evaporators and higher bleach use.

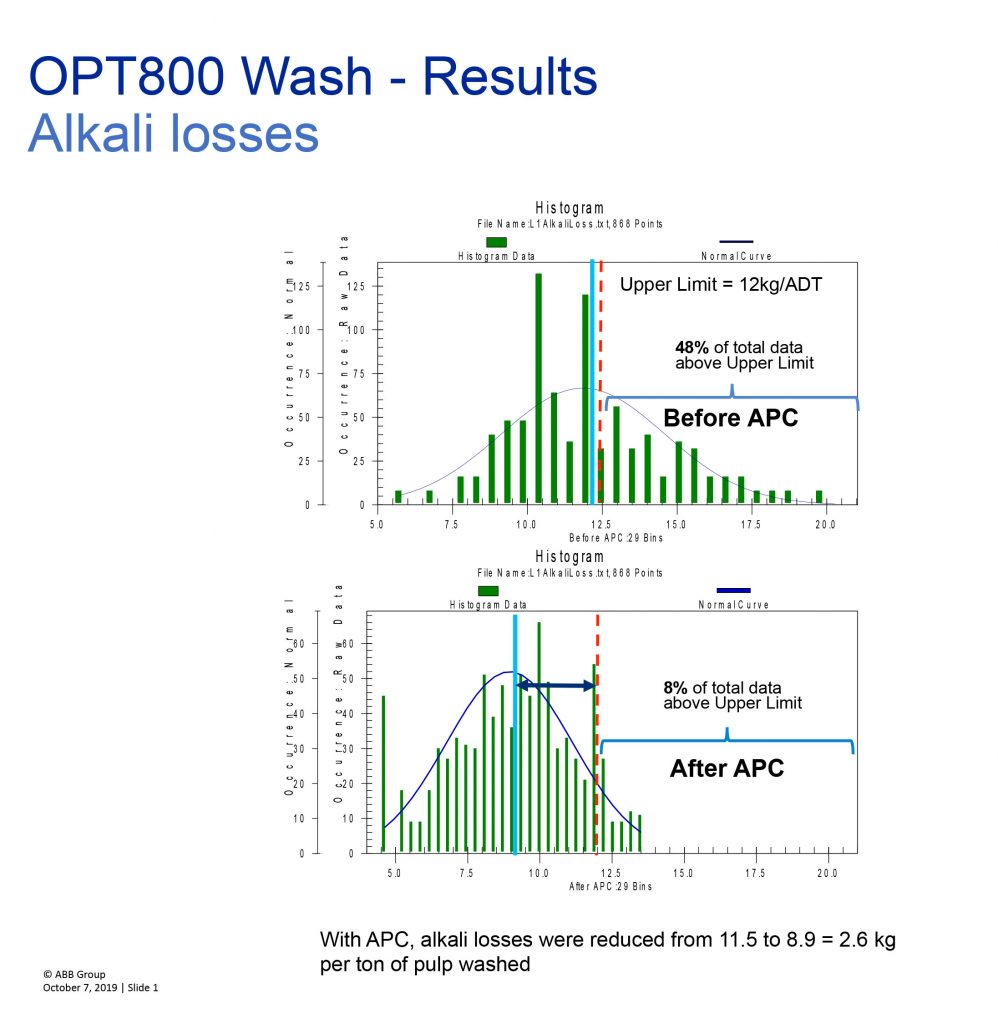

The control strategy used in the OPT800 Wash module involves computing optimal setpoints for (a) the dilution factor in each washing stage and (b) the defoamer charge to maintain the alkali loss at a specified target while respecting constraints on wash liquor inventory, i.e. the filtrate tank levels. This results in reduced usage of fresh water, a decrease in alkali losses and an increase in dry solids in the evaporation liquor, thereby reducing steam consumption in the evaporation plant.

In a recent European application, implementation of this strategy resulted in a 30 per cent reduction in alkali losses, 20 per cent reduction in fresh water consumption and a 12 per cent reduction in steam consumption in the evaporation plant (figure 3).

Figure 3: With APC, alkali losses were reduced from 11.5 to 8.9 = 2.6 kg per ton of pulp washed. Photo supplied by ABB

Recovery area

APC techniques can also be applied in the recovery area of the pulp mill. ABB has developed OPT800 modules for evaporation, causticizing and the lime kiln. A British Columbia pulp mill wanted to reduce fuel consumption while also improving the quality of lime produced in the kiln. By applying OPT800 Lime, they were able to achieve a five per cent reduction in energy consumption and a more consistent residual carbonate in the re-burnt lime.

Similarly, another Canadian mill in New Brunswick was aiming to produce consistent quality of thick black liquor while minimizing steam usage in the evaporation plant. With the implementation of OPT800 Vapor, the mill was able to reduce black liquor density variation by 40 per cent by optimizing steam usage.

Diagnose, implement and sustain

In order to estimate the potential benefits of APC, an initial study of the pulp mill and its behaviour must be carried out. A structured approach is used to work with clients through three stages of each project: Diagnose, Implement and Sustain.

In the Diagnose step, the first objective is an audit of the process along with its measurement and basic control system. Bottlenecks are determined, as well as what can be improved without adding any new controls, for instance by changing operating parameters or existing control loops. Secondly, based on expected variability improvement results, an action plan with an estimate of results obtainable from APC implementation is made with a predicted return on investment.

In the Implement step, first the appropriate OPT module is installed, complete with pulp tracking, MPC, soft sensors and expert controls. The system is then tuned and the mill personnel are trained in using the system.

In the Sustain step, performance is monitored continuously and maintained at the agreed level, working with mill operators and staff. Payment is on a monthly basis and is performance-linked, i.e. payment occurs only when the performance reaches the agreed level. This can be either until the end of a negotiated contract period or on a perpetual basis, depending on the needs of the mill and how the project is structured.

Factors for success

When I asked Badwe whether every APC project has the same success rate, he observed that there are three critical success factors. First, it’s important to have good quality of both historical and live data. This will depend on the age of the underlying distributed control system (DCS); it can be difficult to extract data from older DSCs and to interface the optimization system with the DCS.

Secondly, success depends on having good sensors and accurate measurements. Some measurements are must-have items for success and others are good-to-have. Assessment of the measurement system is included in the Diagnose step of the project. If the measurement system is not up to par, the APC won’t deliver the anticipated results.

Finally, the mill that implements an APC project must be open to not only changing the way they operate their process, but also to allowing the process to be deliberately perturbed, or “bumped.” This latter step is necessary for a certain period during the Implement step, as it provides information to build the process model and understand how the variables interact. Willingness to explore the effects of changing each variable independently builds a better-quality model, which leads to a better quality of control achievable.

Conclusion

Advanced process control has evolved over the last 30 years with the availability of better sensors, better control strategies and cheaper and faster computing power. Driven by the opportunity to have better control over variability and reduce production costs, many more applications of advanced process control are likely to be installed to help pulp and paper manufacturers increase visibility and gain a competitive advantage as overseas competition increases.

_____

Martin Fairbank has worked in the pulp and paper industry for over 30 years and is currently a consultant and technical writer.

This article originally appeared in the Fall 2019 edition of Pulp & Paper Canada.

Print this page